|

SPECIFICATIONS |

||||

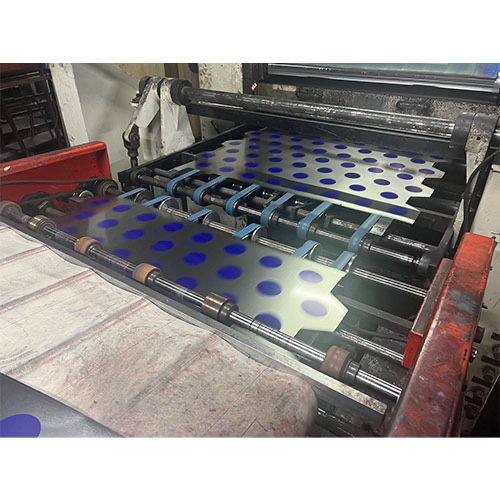

| Machine Speed | 7,500 Sheets/hour (125 Sheets/min) | |||

| Operation Speed | 6,000 Sheets/hour (100 Sheets/min) *Depending on production condition | |||

| Maximum sheet size | 1,145mm x 950mm x 0.4mm | |||

| Minimum sheet size | 710mm x 510mm x 0.12mm | |||

| Maximum printing area | 1,135mm x 945mm | |||

| Printing plate size | 1,160mm x 1,040mm x 0.3mm | |||

| Blanket size (aluminum bar type) | 1,174mm x 1,106mm x 1.9mm | |||

| Feture |

|

|||

English

English Chinese

Chinese Русский

Русский Zhejiang D-Champion Metal Packing Co.Ltd

Zhejiang D-Champion Metal Packing Co.Ltd