Definition:

TFS is only available with one standard coating which is equal on both sides.

Features :

Lower in price than tinplate, tin free steel boasts superior lacquer and paint adhesion, and strong resistance against corrosion. Tin Free Steel has a beautiful, lustrous metallic finish on both sides.

1.Excellent paint adhesion

2.Excellent heat resistance

3.Excellent resistance to Sulphur Blackening

4.Excellent filiform rust resistance

5.Excellent alkali resistance

Uses :

1.Crown Caps

2.Caps, bottom, Easy open end, closures

3.Electric and electronic parts

4.Bearing part, Sealing part

5, Miscellaneous applications such as Tin toys, Candy can, badge, Battery shells…etc

Properties

Compated with ETP, it has special properties:

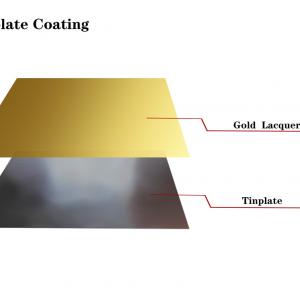

Appearance: TFS will show its particular luster of chromium metal due to different appearances between TFS and ETP, even they’re in the same finish state.

Corrosion resistance: Painted TFS has an excellent characteristic of corrosion resistance, therefore, TFS is painted with double sides usually. It can also be unpainted internal depending on the contents.

Solderability: TFS is not suitable for soldering

Weldability: TFS has a poorer weldability than ETP even though removed the chromium metal coating layer of TFS.

Coating weight: TFS is only manufactured according to one type of coating thickness, while ETP can be manufactured with a series of tin coating thickness standard.

Available size

|

Steel Type |

|

MR,SPCC, Type L |

|

Temper(BA&CA) |

Single Reduced |

T1,T2,T3,T4,T5 |

|

Double Reduced |

DR8,DR9,DR10 |

|

|

Thickness & Tolerance |

|

0.14-0.50mm(Tolerance:±0.002mm) |

|

Width & Tolerance |

|

600-1050mm(Tolerance: -0/+3mm) |

|

Coating |

Metallic Chrome |

50-150 mg/㎡ |

|

Chrome Oxide |

5-35 mg/㎡ |

|

|

Coil Weight |

|

4-10 MT |

Standard:

JIS G3315,ASTM657,GB/T24189-2009

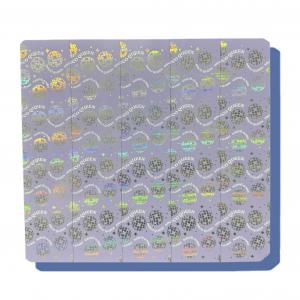

Surface Finishes

|

Black Plate |

Code |

Surface Finish |

Characteristics |

|

Single Reduce |

B |

Bright Surface |

Glazed surface obtained by a thin layer of chromium and chromium oxide deposited on the smooth steel base with extremely fine stone figures by processing. |

|

R |

Stone surface |

Glazed surface obtained after a thin layer of chromium and chromium oxide deposited on the smooth steel base featuring certain oriented stone fugures. |

|

|

R2 |

Stone rough surface |

Glazed surface obtained after a thin layer of chromium and chromium oxide deposited on the smooth steel base featuring certain oriented stone figures, roughness higher than “R” |

|

|

M |

Matte surface |

Matte surface |

|

|

Double reduced |

R |

Stone surface |

Glazed surface obtained after a thin layer of chromium and chromium oxide deposited on the smooth steel base featuring certain oriented stone figures. |

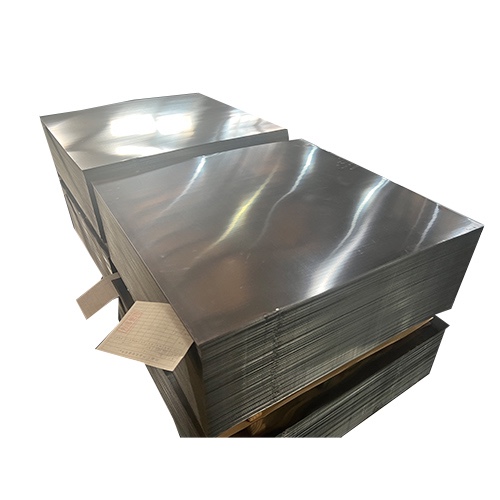

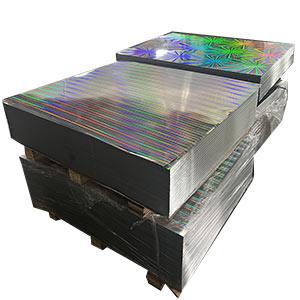

Packaging:

TFS are packed with special care to with stand severe handling in marine transit. Special care is given to prevent rust and scratching. Typical examples of packaging methods are shown as below:

Customized coil I.D(420 or 508) & (horizontal or vertical)

English

English Chinese

Chinese Русский

Русский Zhejiang D-Champion Metal Packing Co.Ltd

Zhejiang D-Champion Metal Packing Co.Ltd