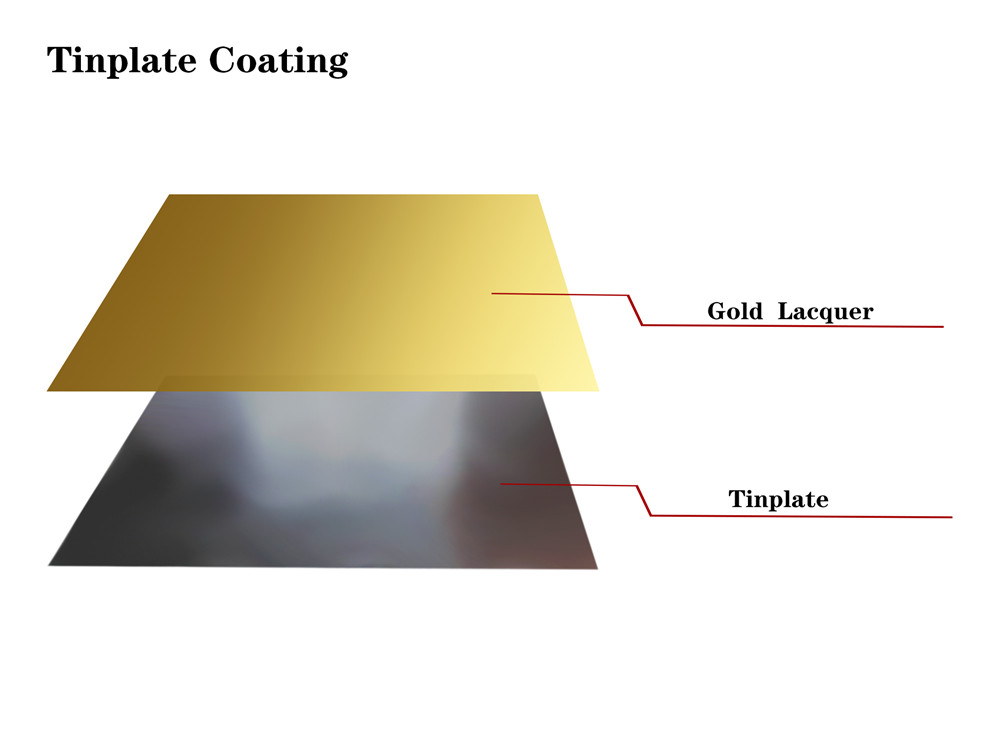

LACQUERED TINPLATE

Tinplate coil need to be coated with a certain gold lacquer coating on the inner surface, in order to prevent the chemical interaction between the filling in the tank and the tank wall and the contamination of the filler by trace elements, It's time to protect the quality of the filler. The packaged product can be stored, transported and sold for a long time without affecting the use value of the product.

It can be divided into internal coating and external coating according to the different sides of the coated tinplate. It can be divided into bottom paint (also called primer), white paint (also called white coating), and varnish .

① Bottom paint. The oil layer and oxide film on the tinplate surface directly affect the adhesion between the printed ink and tinplate. Considering the impact of post-processing on printed products,a colorless and transparent bottom paint is often applied before printing ,to make the printing ink firmly adhere to the tinplate surface.

② White paint. White coatings are mainly used for tinplate prints with white background. Usually, they are applied by roller coating with a coating machine. Generally, the coating can be applied once to achieve the required thickness. The whiteness of the film is good and the gloss is high. At present, most of the printed tinplate products use white paint as the background color.

③ varnish. Varnishing is the last process of tinplate printing. The function of the varnish is to protect the printed pattern, prevent mechanical damage, and at the same time give the surface gloss of the printed product and increase the aesthetics.

According to different purposes, varnishes can be divided into two types: food can varnish and non-food can varnish.

(a) Food varnishes are characterized by low yellowing at high temperatures, high gloss, high hardness, resistance to boiling water and steam sterilization. Non-drying oil alkyd resins, oil-free alkyd resins, and acrylic resins are often used. Configuration.

(b) Non-food can varnish is mainly used for miscellaneous cans such as tea cans and candy cans. Such varnishes are not resistant to boiling water and steam sterilization, but have good stamping resistance, high gloss, and low baking temperature. Soy oil is often used. Alkyd resin, peanut oil alkyd resin and epoxy resin are formulated.

According to different drying conditions, varnishes can be divided into two types: high temperature varnish and low temperature varnish.

(a) High temperature varnish refers to varnishes whose drying temperature is above 150 ℃ during the varnishing process, such as varnishes formulated with epoxy resin, uric acid resin, vinyl resin, etc

(b) Low temperature varnish refers to varnishes whose drying temperature is below 150 ℃during the glazing process, such as amino alkyd varnish.

English

English Chinese

Chinese Русский

Русский Zhejiang D-Champion Metal Packing Co.Ltd

Zhejiang D-Champion Metal Packing Co.Ltd