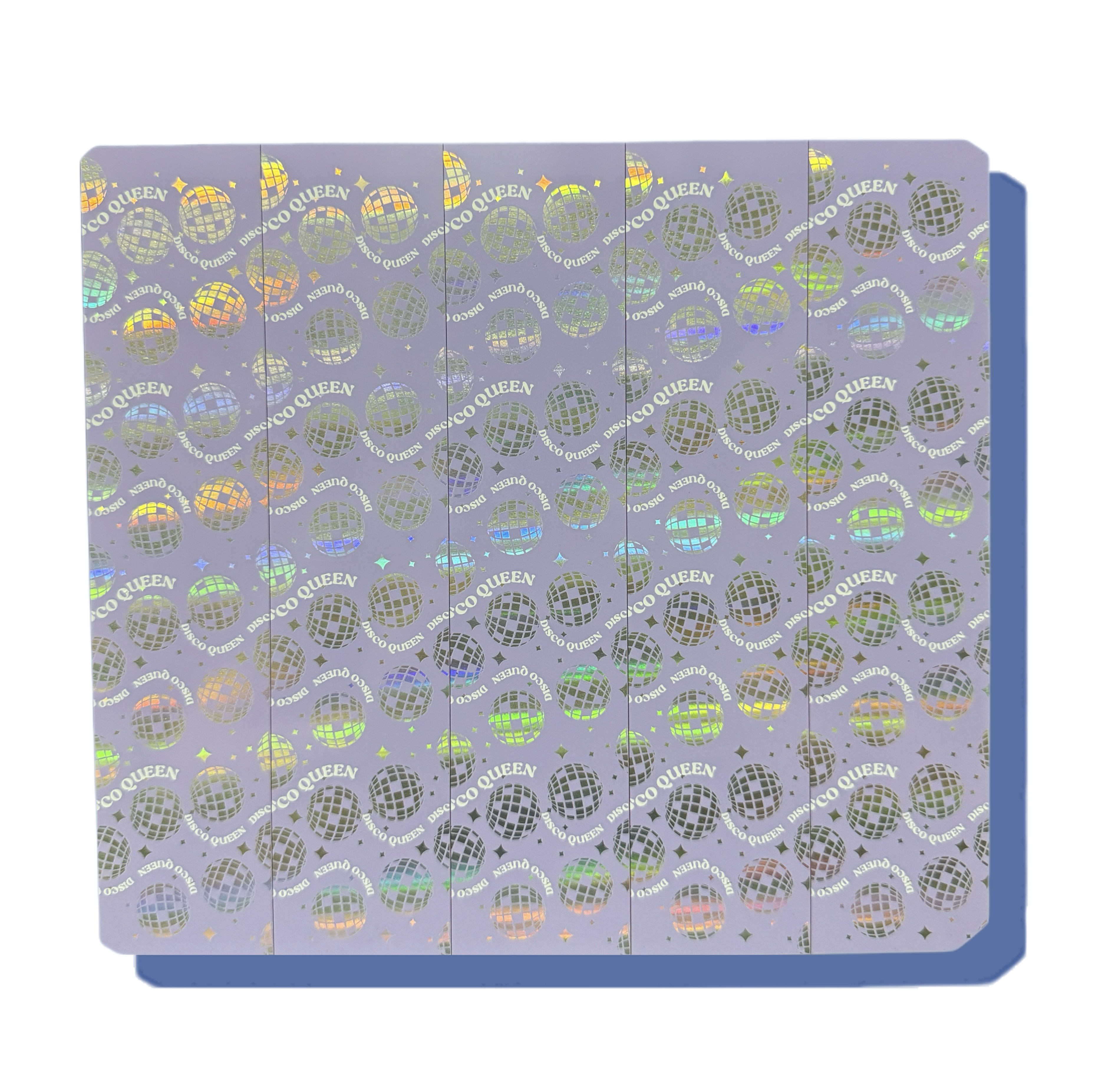

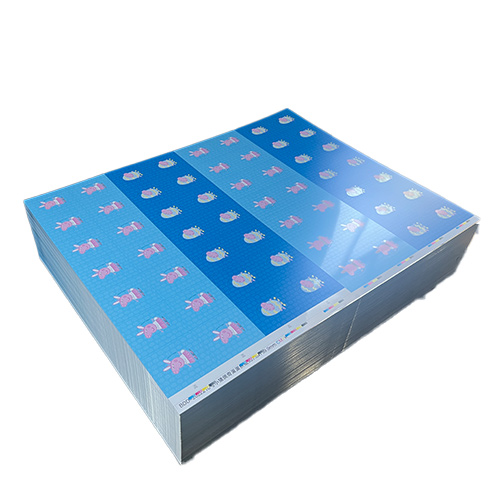

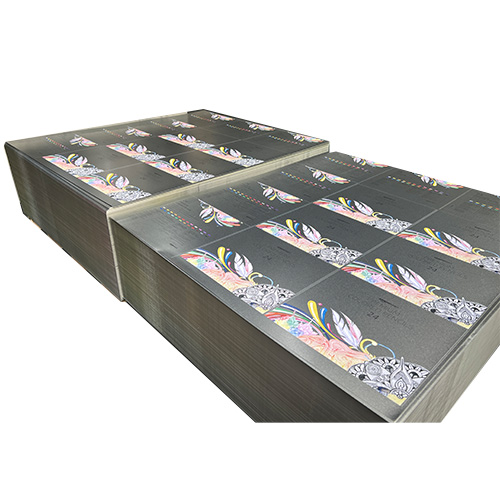

PRINTED TINPLATE SHEET

Offset printing on tinplate sheets involves a specialized process to ensure proper adhesion of ink to the metal surface. Here's an overview of how offset printing is adapted for tinplate sheets:

1. **Surface Preparation**: Tinplate sheets are cleaned thoroughly to remove any oils, residues, or contaminants that could affect ink adhesion. This cleaning process is crucial to ensure a clean and receptive surface for printing.

2. **Primer Coating**: To enhance ink adhesion, a primer coating may be applied to the tinplate surface. The primer helps the ink adhere better to the metal and improves print quality and durability.

3. **Plate Making**: A printing plate is created with the desired design or image. The plate is typically made from a photosensitive material coated onto a metal substrate. The design is transferred onto the plate using photographic techniques and chemical processing.

4. **Ink Application**: Ink is applied to the printing plate. In offset printing, the ink is transferred first to a rubber blanket cylinder before being transferred onto the tinplate surface. The ink is specially formulated for metal substrates, ensuring good adhesion and durability.

5. **Transfer to Rubber Blanket**: The printing plate comes into contact with a rubber blanket cylinder. The image on the plate is offset onto the rubber blanket, creating a mirrored image. The rubber blanket's flexibility allows it to conform to the irregular surface of the tinplate.

6. **Transfer to Tinplate**: The inked image on the rubber blanket cylinder is then transferred onto the tinplate surface as it passes between the blanket cylinder and a pressure cylinder. The pressure ensures proper ink transfer and adhesion to the tinplate.

7. **Drying/Curing**: After printing, the ink on the tinplate surface undergoes drying or curing processes to ensure proper adhesion and durability. This may involve heat drying or UV curing, depending on the type of ink used.

8. **Finishing**: Once the ink is dried or cured, additional finishing processes may be applied as needed, such as protective coatings for scratch resistance or decorative embellishments.

Offset printing on tinplate sheets allows for high-quality, detailed prints suitable for various applications such as packaging, decorative items, and promotional materials. It ensures that the printed designs are vibrant, durable, and resistant to scratching and corrosion.

English

English Chinese

Chinese Русский

Русский Zhejiang D-Champion Metal Packing Co.Ltd

Zhejiang D-Champion Metal Packing Co.Ltd